North America's First Metal Miners & Metal Artisans

Have you ever thought about who the first metal miners and metal workers in North America were? What metal did they mine, where did they mine it, and what did they do with it? In order to find the answers to these intriguing questions we have to look back several thousand years before the birth of Christ.

Large deposits of 99%+ pure native copper are known on the Canadian North Shore of Lake Superior, Isle Royale and the Keweenaw Peninsula of Michigan, and some minor deposits in Northern Wisconsin and Minnesota. Reports of these Lake Superior Region copper deposits were heard by the earliest French explorers of the Great Lakes Region, including Samuel de Champlain in 1608. Champlain received a foot long specimen of native copper from an Algonquin Indian chief and sent it to King Henry IV of France. There were no immediate attempts to locate the source of this copper. However, prior to 1800 there were limited attempts to locate the source of the native copper that was spoken of by explorers and indians of the region. These earliest post-european contact attempts to locate and exploit the copper deposits ended in failure.

By the mid-1840s, when the first modern copper mines were opened in the Keweenaw Peninsula, miners began to find traces of earlier mining efforts. Throughout the Keweenaw Peninsula and Isle Royale, pits and trenches dug into the rock were discovered, some as deep as 20 feet and others only a few feet deep. These pits and trenches showed evidence of copper having been removed from the rock, and in some cases copper was found partially worked out of the rock but still in place. In association with these pits and trenches were found literally tons of grooved and ungrooved hammerstones, as well as some finished copper artifacts (knives, spearpoints, spuds, celts, awls, etc.), copper preforms, and unworked cached copper.

An interesting point of fact is that these old copper workings were found on every major copper lode discovered on the Keweenaw Peninsula and Isle Royale by miners in historic times. It was the presence of these old copper workings which led to the discovery of many of the copper deposits that were discovered and mined in historic times.

Many theories have been advanced as to who these early copper miners were, some both incredible and unbelievable. These fanciful theories run the gamut from Phoenicians to Berbers to Minoans, Bronze Age Europeans to Vikings, but there is no empirical archeological evidence to support any of these theories. While almost anything is possible, I will wait for the demonstration of empirical evidence before believing any of these unproven theories.

Our own Euro-centrist racial bigotry allows some to ignore the obvious, that being that this copper was first discovered, mined and fashioned into tools, weapons and ornaments by the indigenous peoples of the region. Rather than admit that indigenous peoples could have mined native copper and fashioned items for everyday use, some "scholars" would have us believe that the copper was mined and worked by a "virtually unknown race of people" or Euro-Mediterranean peoples. There is, in fact, unbroken continuity in indigenous peoples, based upon artifact and skeletal evidence, in the Upper Great Lakes Region.

There is archeological evidence that indicates prehistoric Native Americans began to populate the area we today call Wisconsin at least 11,500 years ago. The end of the last Ice Age, the Pleistocene Epoch, saw the first human inhabitants arrive in the Western Great Lakes Region. As the glaciers receded vast new terrritories were opened to habitation. These post-Ice Age hunter-gatherer cultures have been named the Archaic Period or Archaic Tradition. In the Great Lakes Region the Archaic Period spanned from about 8000-1000 BC or 10,000-3,000BP (Before Present).

One of the lasting effects of the last glacial period on the Great Lakes Region was the scouring of the rock that holds the copper deposits. This glacial scouring action exposed veins of native copper, as well as shearing off innumerable copper pieces of varying sizes, transporting them miles, or even hundreds of miles to the south. This transported copper, found mostly in glacial gravel deposits, is known as "float copper". It was deposited as the glaciers melted and receded northward. This float copper is found in sizes from that of less than a pea to many tons in weight. I have personally found float copper, with a metal detector, almost 200 miles south of its potential point of original. Float copper was readily available to the indigenous population during the Archaic Period and would have first been found while looking for material from which to manufacture stone implements. Experimentation would have demonstrated that this copper was malleable and could be fashioned into useful shapes. It is only a small step from finding the float copper to eventually finding the exposed copper veins, akin to gold prospectors following placer deposits to their point of origin. We have to realize that the vegetation of the Lake Superior Region was significantly different thousands of years ago than it is in historic times. The amount of forest overgrowth was considerably less, allowing exposed copper veins to be located more easily.

Archaeologists believe that there is some overlap between the Middle Archaic and Late Archaic, especially in the use of copper, and that the copper use which was thought to be characteristic of the Late Archaic actually began in the Middle Archaic and developed over time. The first indigenous peoples who actually mined and utilized the copper were labeled "Old Copper Complex" or "Old Copper Culture" by archeologists. Old Copper Complex, as opposed to Old Copper Culture, is a term used to convey the idea that copper working and usage is a multi-cultural rather than a single-culture phenomenon in North America.

There is disagreement among the archeological community as to the time period to ascribe to the Old Copper Complex. Dates range from over 7000 years BP to 3000 years BP. The greatest disagreement seems to be over the beginning age of the Old Copper Complex. Carbon-14 testing of organic materials found with Old Copper Complex artifacts has established a date of at least 6000+ years BP. Carbon testing of wood remains found in sockets of artifacts in our own collection has produced dates as old as 5900+ years BP. Copper continued to be used into proto-historic times, long after the demise of the Old Copper Complex. Many of the copper artifacts from the Old Copper Complex differ from those of later manufacture, with many of the later artifacts being smaller, less utilitarian and more ornamental. Early European traders found native americans using copper tools and weapons wherever copper was available. Many copper artifacts originated in the post-european contact period, native-americans used worn-out and damaged copper pots and other copper trade items to manufacture arrowheads, knives and ornaments. People have always used what was available to them and copper was available for thousands of years.

Since I earlier stated that there is no verifiable physical evidence of the Lake Superior copper deposits having been worked by those other than indigenous peoples, what evidence does exist to prove that the indigenous peoples were the ones who worked the copper deposits and manufactured the copper artifacts found today?

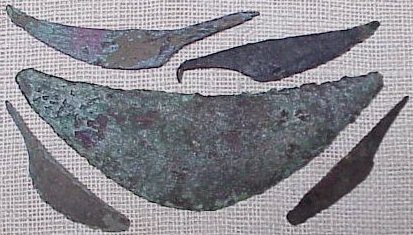

Some of the first hard evidence came, in May of 1945, when two fishermen found some copper artifacts protruding from the eroding bank of the Mississippi River at an old steamboat landing site known as Osceola Landing, in Grant County, Wisconsin. Following this initial discovery, numerous copper artifacts were removed from the site by local collectors and were subsequently identifed as Old Copper Complex artifacts. Old Copper Complex artifacts include, but are not limited to, varieties of socketed spuds (photo 1), crescents (photos 2,3,4 & 5), celts (photo5), fishhooks and harpoons (photo 6), conical spear and atlatl dart points (photo 6), awls, rat-tail spearpoints (photo 7), knives (photos 3,4,8,9 & 10), socketed spearpoints (photos 11 & 12), and other pieces of undetermined utility, as well as beads and bracelets, none of which had previously been found in situ prior to those at the Osceola Site, all previously reported finds being numerous surface finds or isolated caches in Michigan's Upper Peninsula and central to northern Wisconsin.

Photo 1 - 4" socketed spud

Photo 2 - two crescents, one spiral and 4 rolled beads (top)

Photo 3 - three crescent and one tanged knife. (second from bottom)

Photo 4 - four tanged knives and 8" crescent

Photo 5 - crescent (center left), celts, and bracelet (top left)

Photo 6 - conical points (top row), fishhooks and three harpoons (barbed pieces)

Photo 7- Rat-tail spearpoints, 3rd from left has a native silver tang, center point is 3/4 native silver

Photo 8 - 15" gaffhook, knife and spearpoint

Photo 9 - Knives and spearpoint (vertical - bottom)

Photo 10 - knife/scraper and rings

Photo 11 - Variety of spearpoint types

Photo 12 - variety of spearpoint types

These three sites, with their in situ skeletal remains, distinctive chipped-stone artifacts and Old Copper Complex copper artifacts, support the unbroken continuity of indigenous peoples in the Upper Great Lakes. Thus, demonstrating that the Old Copper Complex, a culture, or cultures, of indigenous people, was responsible for the copper artifacts being found, rather than being the product of a visiting "foreign" culture, or cultures.

Another Old Copper Complex site is the Chautauqua Grounds Site at Marinette, Wisconsin. The Chautauqua Grounds Site, and several others, helped in clarifying the links between the mortuary complexes of the Middle and Late Archaic Period and lent additional support to the case for indigienous peoples.

Evidentiary finds at sites in Canada support the findings at the Wisconsin sites. Old Copper Complex artifacts have been found at sites in the Canadian Provinces of Alberta, Manitoba, Ontario, and Quebec. The Morrison Island-6 Site, located on an island in the Ottawa River, was found to contain 18 burials and 276 copper artifacts, including a spud, projectile points, knives, and others. Also of interest was the discovery of worked and unworked copper scraps, indicating copper implement manufacture on the site. A carbon-14 date places this site at 4700BP, clearly an Old Copper Complex Site. The Caribou Lake Site contained a cremation pit with skeletal fragments and tooth enamel remains, along with copper artifacts. Carbon-14 dating placed this site at 3900BP.

While skeleton remains associated with the Old Copper Complex did not become known to acheologists until 1945, many sites where copper tools and implements were manufactured were discovered much earlier in Wisconsin, all originally being surface finds, some Old Copper Complex and some from later manifestations. From the 1870s through the 1920s workshop sites were found that contained large quantities of copper fragments, partially finished and some finished tools and implements. Some of these include sites at Two Rivers (Manitowoc County), 4 sites along the Fox River (Marquette County), a site on the Black River south of Sheboygan, several sites in Waupaca County, sites along Green Bay in Oconoto and Brown Counties. Since the 1960s numerous workshop sites have been identified in Oneida, Vilas, Lincoln, Price and Forest Counties. Workshop sites have also been identified in Michigan at Osceola near Calumet, Chassell, on the Portage Lake Canal, at Dollar Bay, and Hancock, all in Houghton County, as well as several in Mackinac County.

Old Copper Complex artifacts have been found from Alberta in the west to Quebec in the east in Canada, and as far west as North Dakota, as far east as Delaware and as far south as Kentucky in the United States, but the center of the Old Copper Complex is generally agreed to be in Wisconsin. How did Old Copper Complex artifacts come to be scattered so far afield? The answer to this question is obviously trade. The presence, in Wisconsin, Michigan and Minnesota, of many specific types of stone and shell artifacts not indigenous to Wisconsin demonstrate that widespread trading took place throughout North America. This is evidenced by the presence of Wyoming obsidian and salt water shells in the Lake Superior Region.

How did these Archaic Tradition peoples obtain and work the copper that identifies them as the Old Copper Culture? As mentioned earlier, the source of most prehistoric copper was the north shore of Lake Superior, Isle Royale, and the Keweenaw Peninsula of Michigan, as well as glacial float deposits to the south left by the receding glaciers. There are other deposits of native copper (Wisconsin, Minnesota, Tennessee, Pennsylvania, Ontatario) that, while not of sufficient volume to make them commercially viable for modern needs, would have met the limited needs of the indigenous population.

Diorama of Old Copper Complex Indians working a copper vein

One has to ask the obvious question, where did all this mined copper go? Some scholars would have us believe that the vast majority was taken by Phoenicians, Berbers, Minoans, Bronze Age Europeans or Vikings in a huge international copper trade centering in the Lake Superior Region. Logically one has to ask how these foreign miners knew that this copper existed in the first place? Where is the archeological evidence to support these theories and claims? The truth is that the archeological evidence does not exist. There are no identified community or camp sites, no burial remains, and no identifiable artifacts to support any of these theories. Are we to believe that these foreign miners were so environmentally conscious that they took all their garbage from daily living back with them, along with the copper, and what about their dead, did none of them die here? If there had been mining operations on a scale sufficient to produce 500 million to 1.5 billion pounds of copper there would be significant archeological evidence to substantiate that work. All of this evidence does exist to demonstrate that the indigenous peoples were the ones who mined the copper and fashioned it into implements, weapons and ornaments, over a period of as much as 7000 years. One need only analyze Michigan copper and Bronze Age Eurepean copper for common trace elements to see if they have the same point of origin. I have yet to see published information on this analysis.

Sodders' figures of 10,000 miners laboring for 1000 years in an estimated 10,000 pits are pure unsubstantiated bunk. Who counted the 10,000 miners, what archeological evidence exists to show that foreign people were here in any substantial numbers, who estimated the 10,000 pits and on what evidence was this estimate made? The Copper Complex copper pits were actually worked much longer than 1000 years, as proven by archeological evidence. As for the estimated 10,000 pits, who estimated that number of pits and based upon what data? There has never in recorded history been a comprehensive study and tally done of the number of pits, what is the evidence for this "estimated" number of copper pits?

The estimates put forth by Drier and Du Temple are easily debunked. They start with the errroneous and unsupported assumption that the average pit was 20 feet in diameter and 30 feet deep. An average diameter and depth based upon what sample of copper pits? No study of these ancient copper pits has ever determined an average size. Few, if any, pits have ever been reported as deep as 30 feet, (and this is Drier & Du Temples average depth, so some must be even deeper), when in fact many ancient pits or trenches barely scratched the surface by more than a few feet. Twenty feet seems to be the limit on depth of known ancient copper pits and these are few in number.

I am not attempting to denigrate their important landmark work, but I am questioning the validity of some of Drier & Du Temple's assumptions. Their assumption of 5000 pits has no supporting documentation as a comprehesive study of the number of pits has never been undertaken and published. Their 5% to 15% copper content is flawed since copper content can run from zero to 100% (mass copper). The amount of copper in the country rock isn't constant or regular, a very expensive fact learned by many early modern mining companies. All of the numbers offered up by Drier and Du Temple are based mainly on conjecture, with no basis in fact.

Leaving unsubstantiated theories, let's examine how the Old Copper Complex people produced their copper implements, weapons and ornaments. Unless copper is cast, and no empirical evidence yet exists to demonstrate that the Old Copper Complex possessed the technology to cast copper, it must be cold hammered, which produces brittleness in the copper, or annealed (worked, then heated to prevent brittleness). Small stone hammers could be used to form basic shapes and then edges could be sharpened or shaped by being stone-ground. Given the primitive means of working the raw copper, the workmanship on many of these artifacts must be judged as excellent.

The chunks of copper were first pounded into "preforms" which were basic shapes that could be used for more than one type of implement. These were followed by "blanks" which were the overall size and shape of the finished item but were not completed for use. Finally, there was the finshed artifact which had all the characteristics of a usable implement, weapon or ornament which might include such features as a sharpened edge, as in the case of a knife, scraper or spearpoint, a sharp point, as in the case of an awl, fishhook or spearpoint, or a socket, as in the case of some types of spuds, harpoons, knives, spearpoints and atlatl dart points.

As copper becomes brittle when pounded repeatedly, it must be heated to a red-hot state (annealed) to again make it malleable before it can be worked further. Modern experimentation with this process has shown that as many as 30 pound/anneal cycles are necessary to produce some tools. Once formed, tools requiring a sharp edge or point could be honed using fine-grained local sandstones or other uniformly abrasive flat stone surfaces.

We have artifacts in our collection in which as many as six distinct overlapping folds appear to exist. This folded appearance can be found in all types of copper artifacts - spearpoints, knives, awls, atlatl dart points, crescents, spuds, and others. The experience of modern day artisans who have produced tools through the use of native copper heated (annealed) in wood fires is that some copper, when worked, splits apart and appears as though folded. While this does not disprove that folded copper was used to make tools, it does bring its use more into question as more research is conducted and more items are produced by old methods.

We have self-collected hundreds and hundreds of worked and scrap pieces of copper associated with artifact finds that point to the presence of numerous manufacturing, or workshop, sites. We have also found worked copper "bars" (for lack of a better term) which are up to 1 1/2" square and 8" long which were most likely used as trade items as they were easily transportable in that form. These bars also demonstrated that the specific piece of copper could be worked, giving it more value in trade. Modern experimentation in manufacturing copper tools and weapons has shown that many pieces of copper are not suitable for manufacturing purposes due to natural impurities and flaws within the copper. Thus, a worked copper "bar" would demonstrate the workability of a specific piece of copper, increasing its trade value. The largest single Phase II worked piece of copper we have acquired measures approximately 6 1/2" x 6" x 1" and weighs 4 1/2 lbs. Phase I worked copper is copper that has been worked on a single plane, that is, copper that has been pounded flat. Phase II worked copper is copper that has been worked on more than a single plane, copper that has been pounded flat and pounded on the sides.

The presence of gas bubbles on the surface of a few Copper Complex artifacts has been taken by some as evidence that these artifacts were in fact cast from molten copper. I have yet to see empirical evidence to support this copper casting hypothesis, no molds, no furnaces, no copper drippings and no slag as found with ancient or historic foundry operations and no partially completed artifacts with a casting sprue still in place. What has been shown to be true through modern day experimentation is that gas bubbles are rountinely formed in the pound/anneal process. Gas bubbles have been shown to form when copper is heated to a red-hot state in the annealing process due to gas expanding and attempting to be released. The vaporization of impurities in the copper can account for these bubbles. There would actually be more surface gas bubbles observed if it were not for the highly oxidized condition of many copper artifacts which has obliterated them. This phenomenon has been observed numerous times in the process of copper tools being fashioned by modern day artisans using the pound/anneal process. (Link to article on this subject)

Copper preform

Copper knife blank

Copper preform

Copper preform

Unfinished blank for a conical point

Copper preform

Copper "bars" (second from bottom measures 1 1/2" x 1 1/2" x 8") They are not flat as they appear but rather squared.

This page was last updated on: July 6, 2022

7" Tanged Spearpoint

4 1/2" Socketed Spearpoint

Other Side of Socketed Spearpoint

7 1/2" & 5" Awls

Preform with Native Silver (center)

4 1/2" Tanged Spearpoint

3" Conical Point

3" Conical Point Showing Folds

4 1/2" Crecent Knife

5 1/2" Spatulated Tool

3 1/2" Rat-tail Point

3 3/4" Step Socketed Point

5 1/2" Conical Socketed Point

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

Please contact me if you have copper artifacts to sell

7" Long Copper Bar

It was not until June of 1952 that another Old Copper Complex site was discovered, this occurred on the western edge of Oconto, in Oconto County, Wisconsin, near the Oconto River. Thirteen year old Donald Baldwin was playing in an abandoned gravel pit when he found human skeletal remains. Initial investigation by the Oconto County Historical Society revealed numerous burials accompanied by copper artifacts. The site was soon more extensively examined by staff from the Wisconsin Historical Society and Milwaukee Public Museum. It was found that a major portion of the original burial site had been removed by commercial gravel operations in the 1920s but 45 burials were identified as remaining. Associated with these burials were Old Copper Complex artifacts in the form of 7 awls, 4 crescents, 3 clasps, 1 socketed spearpoint, 1 fish-tail spearpoint, 1 ovoid spearpoint, 1 fishhook, 1 coiled copper bead, 1 bracelet, and 1 spatulated artifact. Awls were found to be the most frequently occurring artifact, just as they had been at the Osceola Site.

In 1953, a Late Old Copper Complex site (approximately 3000BP) was discovered in Algoma Township, Winnebago County, Wisconsin, on the south shore of Lake Butte des Mortes, on the farm of Matt Reigh. The Reigh Site, like the Oconto Site, was uncovered in part by modern commercial gravel operations. Burials of 43 individuals were uncovered along with numerous copper artifacts identified as Old Copper Complex. Prior to the archeological investigation being undertaken, as with the earlier Oconto Site, an unknown number of burials had been destroyed by commercial gravel mining operations.

Of great importance was the discovery, by professional archeologists, of skeletal remains in association with many copper and chipped stone artifacts. It is estimated that there were approximately 500 burials at the Osceola Site. The major contribution of the Osceola Site was the demonstration of a cultural complex that included Old Copper Complex artifacts. The Osceola Site tied Old Copper Complex artifacts to a distinctive chipped stone industry and burial complex. The fact that cemeteries were found is evidence of long-term attachment to particular places which were returned to again and again, this illustrates long-standing connections between native people and the lands they occupied. Additionally, the inclusion of artifacts with the dead is an indication of belief in an afterlife and the desire to honor the dead with appropriate ceremonies. While not the earliest evidence of burial ceremonies in North America, it is one of the most obvious manifestations.

How were these people able to extract the native copper from the hard igneous rock in which most of it is found? One possible answer to this question is fire, water and stone. One possible method holds that when a copper vein was discovered, fires were built on the rock and kept burning until the rock become very hot, water was then thrown on the heated rock and the rapid cooling fractured it, thus making it easier to free the copper from the surrounding rock This process would be repeated numerous times before these ancient copper miners then began using stone hammers to break the copper free from the now fractured rock. Stone hammers could also be used to break rock without first fracturing it by heating and rapid cooling, but with much greater difficulty. Stone hammers were also used to break off pieces of copper small enough to be worked. Large pieces of copper are difficult to cut even with modern steel chisels. It was to the advantage of these ancient miners to extract and use smaller pieces of copper whenever possible. In this case bigger was definitely not better for producing copper tools and weapons. Examination of copper artifacts in collections today indicates that two or more smaller pieces of copper were occassionally incorporated into the manufacture of a single artifact.

The stone hammers used were of two varieties, grooved and ungrooved, or altered and unaltered. Grooved hammerstones would have handles attached through hafting, while the ungrooved hammers were merely held in one or both hands. The majority of hammerstones found on Isle Royale tended to be of the hand-held ungrooved variety, with far fewer grooved hammerstones in evidence than on the mainland. Those on the mainland were ungrooved and grooved, with a much larger percentage being grooved than was the case on Isle Royale. The grooved hammerstones found on Isle Royale tended to have less effort put into their alteration than grooved hammerstones found on the mainland, which have deeper and fuller grooves. Hammerstones were generally symetrically rounded beach stones of hard igneous rock. Hammerstones have been found weighing from 1 pound to more than 30 pounds. The grooved hammerstones range from partially to fully grooved and from barely grooved to deeply grooved. Early modern-day miners removed literally tons of hammerstones from individual ancient mining sites in the Keweenaw Peninsula and on Isle Royale in the 1800s. Hammerstones are still found on the mainland today, as well as on Isle Royale where they are protected from collectors due to Isle Royale's status as a national park. We have found complete and damaged grooved hammerstones, two examples appearing in photos to the right, at several locations in the Keweenaw Peninsula.

There have been incredible, but totally unsubstantiated, claims made as to the time and manpower required to create the ancient copper pits and as to the amount of native copper that was actually mined prior to modern times. Beginning with Drier and Du Temple in 1961 and Mertz in 1967, through Sodders in 1990, figures of .5 to 1.5 billion pounds (yes billion, not million) have been put forth. That is 250,000 - 750,000 tons of copper. Sodders postulates "it is believed that as many as 10,000 miners, labored some 1,000 years, in an estimated 10,000 Copper Range pits". Drier and Du Temple get to their figures with the following faulty assumptions in their important 1961 work "Prehistoric Copper Mining in the Lake Superior Region": "If one assumes that an average pit is 20 feet in diameter and 30 feet deep, then it appears that something like 1000 to 1200 tons of ore were removed per pit. If the ore averaged 5% or 100 pounds per ton then approximately 100,000 pounds of copper were removed per pit. If 5000 pits existed, as earlier estimates indicated (and all are copper bearing), then 100,000 pounds per pit in 5000 pits means that 500,000,000 pounds of copper were mined in prehistoric times- all of it without anything more than fire, stone hammers and manpower. If the ore averaged 15% copper and if more than 5000 pits existed, then over 1.5 billion pounds of copper were mined". Where did these figures come from, who created them, based on what evidence produced by whom? Their very first sentence "assumes" the average size of a pit and is postulated on three unsubstantiated "ifs" in their statment.

Large 9 1/2 lb. 3/4 grooved hammerstone

Small 2 lb. fully grooved hammerstone

While shaping through pounding would achieve the general overall shape of the copper piece it would take grinding to achieve the finished product. Grinding, whether done today or by ancient artisans, is a manufacturing technique that achieves multiple goals. Grinding can be used for metal removal, that is, to remove excess metal. Grinding can be used to bevel and sharpen a tool or weapon edge. It can also be used to achieve uniformity of thickness. A study of copper artifacts in collections today will demonstrate the presence of grind striations on the lateral edges of copper tools and weapons. Grinding was apparently used, with pounding, to first achieve the rough configuration of a copper tool, to produce ridges and bevels, and to shape sockets. After additional pounding the copper piece was brought to a finished state through fine grinding.

It is obvious that grinding was used to sharpen the fine points of awls and fish hooks, as these points could not have been produced by pounding alone. Just as the double and asymmetrical beveling found on spear points, knives, and celts could not have been achieved solely by pounding. This same grinding and honing was later required when iron and steel replaced copper and bronze for weapons and tools on other continents.

Grinding was achieved through the use of locally available sandstones and other rock, which could be used just like the various rough to fine grit sandpaper and grinding wheels in use today. In the Keweenaw Peninsula, the Freda and Jacobsville sandstones were readily available to ancient artisans. The Freda Sandstone is a red/brown ferruginous sandstone, siltstone, and mudstone. This formation is at least 3700m thick. The Jacobsville Sandstone (over 3000m thick) is a red to white coarse to fine-grained feldspathic quartzose sandstone deposited in a rift flanking basin to the east of the Keweenaw Fault. Both of these sandstones are found in outcroppings, and in glacial till. Indigenous peoples in the Lake Superior Basin had all the tools necessary to mine native copper and fashion it into useful articles for their everyday use.

Copper did not define the people of the Old Copper Complex, or those who followed, archeological evidence would suggest that copper had utilitarian, and perhaps ceremonial, uses but was not essential to their existence. Copper in the Lake Superior Region was a complement to stone materials, it never replaced stone. Native copper had a place in the lives of indigenous peoples for at least 7000 years, up to the 18th century.

It is the amateur archeologists, indian artifact collectors and metal detectorists who have defined the fullest extent of Old Copper Complex sites. There are not enough professional archeologists to scour the areas traversed by amateur archeologists, artifact collectors and metal detectorists. My father and I are aware of many sites, as are other collectors, that are unknown to professional archeologists, and which have produced, and continue to produce a multitude of copper artifacts. Finds by amateurs have established that there are Old Copper Complex sites scattered throughout Wisconsin, Michigan, Minnesota and Ontario, far more than have been reported by archeologists and archeological journals in recent times. As metal detectors have become more numerous and more sensitive, more and more copper artifacts are being found in areas where they were not previously reported.

While not professional archeologists, my father and I have collected Old Copper Complex artifacts for more than 35 years and between us have amassed a collection of over 3800 copper artifacts, about 3000 of which have been self-collected, as well as some stone and pottery artifacts (different period) collected from the same area as the Old Copper Complex sites. Our collection includes copper artifacts from Wisconsin, Michigan, Minnesota, Illinois, Kentucky, Iowa, North Dakota, South Dakota, New York, Manitoba and Ontario.

When hunting artifacts we log each find as to type, measurements, location and date found, produce a sketch of each artifact and photograph the site. Our finds come from farm fields, construction sites, river banks, and lake shores, we do not despoil archeological sites with our collecting. We steadfastly refrain from excavating burials although we know of their locations, considering this action by those other than a professional archeologist to be grave robbing. Unfortunately most professional archeologists look upon artifact collectors who use metal detectors with disdain, unworthy of serious recognition and seem to place them in the same category as "pot hunters". However, I would argue that the artifacts that we, and others, collect would otherwise remain buried and be unavailable for study. We have made our collection available for study and have been visited by archeologists for that purpose. Without artifact collectors like us the true extent of the Old Copper Complex would not be as well defined as it is.

All artifacts pictured on this website are from the collection of David Johnson, and the late Dr. E.W. Johnson. These artifacts were all collected on private land with the permission of the land owner, and no burial sites were disturbed.

The collecting and study of Old Copper Complex artifacts is an interesting adjunct to my overall mining artifact collection. Click on "My Mining Artifact Website" below to see some of my mining artifact collection. To see additional Old Copper Complex artifacts in our collection click on the first button below. The second button will show you where artifacts in our collection were found. The third button below will take you to sources used for this website. Button four below will take you to my "Artifact Collecting" site showing where many of our artifacts were found. Button seven below will take you to other Copper Culture related websites.

| ||||||

Tool with mushroomed end

| ||||||

Tool with two mushroomed ends.

| ||||||

3/4" Bead

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

| ||||||

7 3/4" Socketed Knife

THE OLD COPPER COMPLEX

THE OLD COPPER COMPLEX

| ||||||

A variety of copper artifacts, the rat-tailpoint on the upper right is 6 3/4" long